The top 5 products Engineers Specify for Packaged Sewer Lift Stations.

Engineers are creatures of habit just like the rest of us belonging to the human race, but only to a degree. Most civil engineers have a special trait within them that limits that basic human trait that makes humans a bit robotic in nature. There are some engineers that when it comes to writing specifications for the Packaged Sewer Lift Station they just look at “boiler plate specs” of past jobs. For the most part I believe that engineers design around the premise of “quality in, equals’ quality out”

It is with that thought in mind that I have put together The Top Products Engineers Specify for  Packaged Sewer Lift Stations.

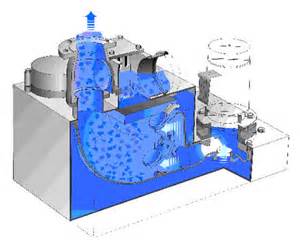

Packaged Sewer Lift Stations.

Let’s start from the bottom up for those products that seem to find their way into the Packaged Sewer Lift Stations.

- The most common type of station specified in the Packaged Sewer Lift Station market is of the submersible duplex design. This type of station, made by a number of packaged station builders around the country utilizes the benefits and simplicity of the submersible pump and motor design. With the advent of sealing flange discharge ells and guide rails for easy retrieval of the pumps the steady growth and acceptance of the Packaged Sewer Lift Station was assured. For those municipal workers who are charged with the maintenance of a dry prime surface mount centrifugal stations the acronym NPSH becomes a very important element of moving liquids and loosing prime is a real concern in these stations. So, the verdict is in, the submersible Packaged Sewer lift Station is often specified.

- The oxymoron of a clean Packaged Sewer Lift Station comes to mind with this next often specified product. The EZZ-Klean™ method is a large 6” HDPE Vacuum pipe usually of the same size as the vacuum truck suction pipe coupled to a wide mouth suction head that is placed directly on the bottom of the wet well floor. This product combined with the smooth, non-stick characteristics of our next most specified product makes for a nice 1-2 punch in the easy cleaning of sludge and sometime hard foreign objects from rocks to clinker of varying kinds. Looking for the key or hatch wrench in an overflow condition has brought to light just how easy the EZZ-Klean ™is to hook up to in an overflow condition.

It is easy to see why the EZZ-Klean™ joins the top product list for Packaged Sewer Lift Stations. - The “strong but slick stuff”, GSE Stud Liner. This High Density Polyethylene is slick. Engineers love it because it endures the test of time. It is highly impact resistant so if a workmen s wrench drops from above; no worries the wrench will barely mar the liner; try that with a fiberglass liner! I guess you can see why fiberglass bathtubs are not exactly the choice for those in high ends homes, however they are the predominant tub in mobile homes, and i.e. they are cheap. Here is the main reason the engineering community is lauding the HDPE lined Packaged Sewer lift Station.#1 HDPE It is very durable, HDPE has a very low co-efficient of friction surface and its lower priced by about half as compared to the fiberglass tub. Finally I said the fiberglass option was cheap, well that is only in a mobile home, because the fiberglass bottom is controlled primarily by one company you the engineer are paying for one very expensive tub. Most engineers agree and many specify GSE, Stud Liner.

- The pumps that do the heavy lifting in the Packaged Sewer Lift Station are Flygt-“N-Clog” submersibles a xylem brand. The Flygt submersible tried and true roto-dynamic pumps are engineering at its best. Other pumps manufactures make excellent submersible pumps. KSB and a few others have stood the test of the sewage wet well and came out as a top rated industrial effluent pump. That being said how Flyght stands out above the rest of the pump manufacture is that the Flygt Team of professionals simply show up. Engineers specify the N-Clog submersible because first off they are great pumps, but day in and day out Flygt/Xylem representatives are present in the trenches, engineer’s offices, bid openings and even on-site when the Packaged Sewer Lift Station is placed into service.. The growth in the share of the market that Flyght continues to capture is a bundle of three things. First the anti-clogging of the n-pump is a welcome relief for public works managers charged with the maintenance and operation of Sewer Lift Stations. The pumping industry has at its biggest challenge to reduce the energy use of pumps. Flygt –Xylem is on the cutting edge of energy savings in their many pump lines. Couple the technology with Xylems informed workforce and it’s no wonder there pumps are preferred by those professionals in the Packaged Sewer Lift Station industry.

- The structure we all need, at least us in the Packaged Sewer Lift Station need the concrete pre-cast structure as supplied by Oldcastle Concrete Wilsonville, now Hanson Concrete. For over 40 years Oldcastle precast has been specializing in creating and delivering millions of tons of high quality precast products. As proof of Oldcastle market approval nearly every civil engineer office has a product spec catalog from Oldcastle concrete. The 1-2 punch that cements Oldcastle as a top supplier for the Packaged Sewer lift Station is the Contractor also appreciates the smooth glass like finish that is the distinct characteristic of the casting process of Oldcastle Concrete products.

There are many other fine products that go into the Packaged Sewer Lift Station. We just don’t have the time to write a book on all the individual components that make up the “packaged Sewer Lift Station” Maybe I should, I am sure it would be a #1 best seller, being such an exciting subject how could it not be.

Stay tuned for other interesting topics in the weeks to come and we’ll “See you at the station.”