The decision to purchase a Packaged Waste Water Pump Station “Made Easy”

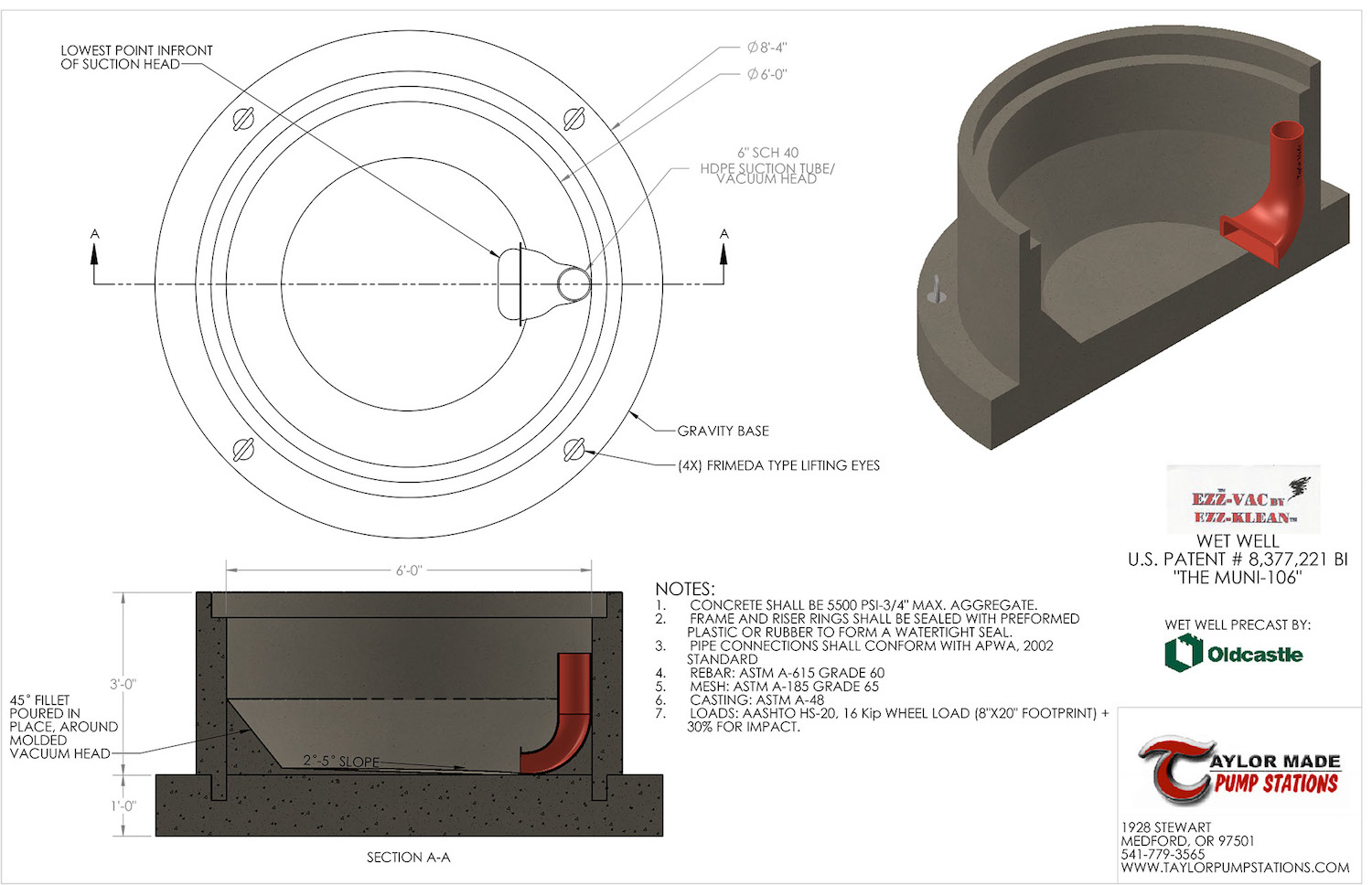

Nice, to’ see you at the Station”. I’d like to discuss with you your decision to purchase a “Packaged Waste Water Pump Station”, and hopefully make the purchasing decision a little easier. I am going to “pump up” the benefits of the new Taylor “EZZ™ Klean” waste water pump station, for just a moment, then move on to more basic considerations that I believe are important in the complete package purchase. The Taylor “EZZ™ Klean Waste Water Pump Station. Is the only packaged pump station on the market today with the benefits and ease of cleaning is in the name itself! The Taylor “EZZ-KLEAN” Packaged Waste Water Pump Station employs a United States Patented design that makes cleaning of the station easy or “EZZ”. The packaged waste Water pump station is the topic of this blog so we are not going to address the option of an assembled and built in place waste water station. The Waste Water Pump Station with all its configurations and options as well as the option of a Dry Prime surface mount or submersible waste water station are simple in design. The surface dry prime arrangement will be the subject of another blog at a later time. The components of a submersible waste water station all of which need periodic maintenance, consist of the Wet Well, the pumps, (most commonly a duplex arrangement) along with guide rails and discharge elbows; Plug Valves and Check Valves along with a valve vault are part of the package. Electric equipment in the form of a motor control center with varying options of frequency drives and programmable logic controls complete the base options for a waste water pump station.

This blog is not covering whether you the, Professional engineer, Public Works Official or Private Developer or Contractor buys a” Chevy or a Ford” pump. That will be a product of how much technical data and research you perform on the specific pump and motor and considering all the information provided by sales representative along with the input provided by the municipality and their representative.

“Best Management Practices means Best Maintenance Practices when it comes to the Waste Water Pump Station”

Anyone involved in the waste water industry knows of the benefits of “BMPs” as it applies to the Waste Water Pump Station. The decision to purchase a packaged waste water pump station should be made with emphasis placed on the ease of maintenance and cleaning of the station. Design features inherent in the Packaged Waste Water Station effect maintenance costs, but few purchasing agents give much credence to this fact in their buying decision. After a career in the waste water pumping industry, mostly as a Project Manager involved in the installation of waste water pump stations, I know that it’s important to consider many factors related to the quality of the components as well as long term maintenance costs of the waste water station. The effects of purchasing a Waste Water Pump Station with difficult maintenance aspects can be much like purchasing a house with a poorly constructed foundation, I.E. neither instance is easy to fix. If you are the individual responsible for the final specification of the waste water lift station that is to be placed into service can we assume you at a minimum looked at the long term maintenance and cleaning costs of this sizable capital investment. There are the basic items of a packaged waste water lift station that will contribute to the end quality of the station. These Items include Pre-marked lid socket receiver for the guide retrieval pipe. This feature is built in to insure that the guide rails for pump retrieval are placed precisely vertical. This feature seems so basic that one might think it is supplied on every packaged waste water station; the fact is, it is not. The purchasing agent should request that the Packaged Waste Water Pump Station suppliers have the option of providing additional sealing options at each joint of the wet well. This includes HDPE bands “electro-fused” and placed around the inside of each barrel section, making an infiltration issue very remote. Remember the pumping of ground water is a kilowatt robbing fact that is assured to increase in costs as power rates are assured to go up. What are the features of the Packaged Waste Water Pump Station that will inhibit Hydrogen Sulfide action? The premier method of preventing hydrogen sulfide corrosion of the concrete is to line the interior of the wet well with a 30 mil thick layer of HDPE, or a similar coat of an epoxy product. Another quality control measure that most established waste water packaged pump station suppliers put forth is to have all stainless steel vents and hatches plastic vacuum wrapped. This of course helps to defend against iron oxides that are prevalent in the cutting of ferrous pipes and other steel products. Consider specifying the EZZ ™Klean device as a simple access tube and vacuum head for its long term benefit of cutting the time in removing debris and harmful build up in the wet well.

It is our goal at Taylor Pump Stations to offer you the options that will produce savings in having a Waste Water Pump Station that will withstand all the harmful effects that a waste environment has to endure and will make for an easier and safer station to maintain.