Be Sure Your Stormwater Lift Station Meets DEQ Regulations

The experts at Taylor Pump Stations understand the legal fine points and complexity assuring that your stormwater lift station meets DEQ regulations and specifications. DEQ specifications are complicated and difficult to understand. When you work with Taylor’s experienced team, you can be certain that you have nothing to worry about.

Will Your Stormwater Lift Station meet DEQ Regulations?

The Purpose of DEQ Stormwater Regulation & Concern for the Environment

Runoff from metal and bitumen roofs, as well as runoff from asphalt parking lots, contains petroleum and other contaminants. These need to be reduced before runoff can enter our waterways. Your pump station must comply with DEQ purification requirements and retention times while simultaneously meeting peak flow demands. Top engineering firms choose us again and again because of our ability to successfully make both happen.

Many Western states now apply strict quarterly monitoring to stormwater runoff. Operators face fines when wastewater contaminants, such as metals, oils, chemicals or any of 126 varying substances exceed permissible limits.At Taylor, we understand these permissible limits so you don’t have to. We design lift stations that work with purification systems ensuring your compliance.

How Taylor Assures Your Lift Station Complies with DEQ Specifications

Methods for purifying water

Methods used to to retard the movement of harmful pollutants and reduce contaminants are retention, timed dosing, earthen bio swales with a sub strata of sand medium and weirs or baffles placed within the treatment cell to allow each feature to retard the movements for harmful pollutants.

Our Lift Station Models and Process

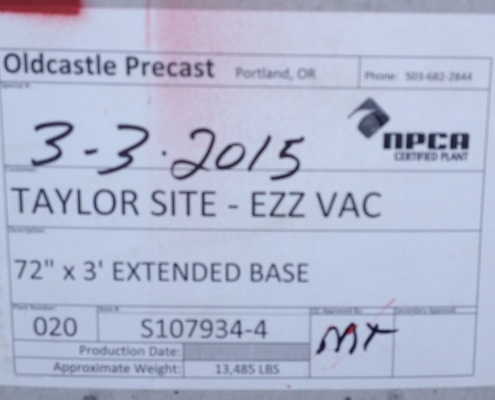

Our lift stations have a variety of flow handling capabilities, making them perfectly suited for stormwater applications. We most often use Muni 108™️, Muni-105™️, Muni- 106™️ for stormwater.

Design engineers work with Taylor Pump Stations personnel to assess the flow requirements and coordinate specific pump and impeller design with the control features to optimize energy use and overall efficiency of the treatment system. Engineering sends peak flow and low point data to our pump application tech so we can start matching the pump and control panel that will produce the best efficiency model to move the water.

The Base Siemens 10 point PLC is the controller we most often use for stormwater applications. Muni 108™️, Muni-105™️, Muni- 106™️ all use this controller. This simple but efficient controller offers multiple functions from alarms, to partly optimizing flows and basic call outs like pump hour meters.

We Know the Specifications and Ensure that Your Stormwater Lift Station meets DEQ Regulations

The new, stricter regulations propelled us to perfect and offer ready made system for stormwater treatment. Leading North West environmental and engineering firms regularly choose the industry leading Muni -105™️, Muni-106™️ and Muni-108 to fulfill a wide range of runoff and flow requirements.

Our company’s identifying green color signifies our commitment to build green. The color comes from the Enviro-Green™️ Hi- Build Epoxy that seals our wet wells.

Experience and Compliance in Other Industries

Taylor Pump Stations has 40 years of experience meeting unique demands and strict regulations in numerous industries. We successfully address the high biological oxygen demand that is intrinsic in the food and spirits industry. We find solutions for moving liquids of varying temperatures and viscosities with energy efficiency and corrosion protection. This vast storehouse of experience and problem solving from other industries informs our work with stormwater lift stations.

Corrosion shortens the life of almost all components in a lift station. Because of our extensive experience with corrosive liquids, Taylor Pump Stations believes we can give you, our customer, double the value in a packaged lift station purchase by doubling its mean time before failure.

Photo by Atilla Bingöl on Unsplash

Public Domain https://commons.wikimedia.org/wiki/File:Shemya_island_Cable_Bowl_N_shore.jpg

Public Domain https://commons.wikimedia.org/wiki/File:Shemya_island_Cable_Bowl_N_shore.jpg