“See you at the station” “At last, options for a sewer lift Stations that must be by-passed”

The call came in from New York, and immediately I seen the light or in this case the fright as the Gentleman on the phone begin to discuss the issue of by-pass pumping. The location of the existing pump station was at a mall parking lot close to the entrance of Macy’s department store. The existing Sewer Lift Station was a conventional submersible design that the developer had little information on. Taylor Made Pump Stations has been design/planning complicated sewer by-passing for the placement of our patented EZZ-Klean™ station for years and this project definitely had my attention.

The best pump by-pass plan is usually designed by a licensed engineer with good error and omission insurance! On by-passing, we don’t plan to fail we fail to plan!

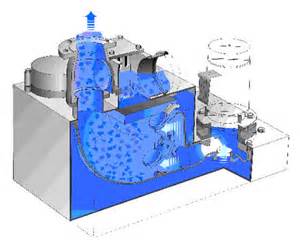

It really is not rocket science to build a packaged sewer lift station. Most of us in the industry understand the importance of every component fitting to a “T” or a “WYE” in the case of the piping connections of a packaged sewer lift station. This fact is so applicable to the sewer by-pass piping connections. This very astute customer wanted to be assured that our Taylor Made Pump Station was not a generic fit all “Sewer Lift Station” but would be applicable to this specific Sewer Lift Station in front of the Macy’s in Manhattan! Most pump station manufactures do not list pump station by-passing as one of their specialties. Taylor Made Pump Stations works with partners and professional associates including “Rain for Rent” and “ Thompson Pump”. These two entities offer technical expertise and are most knowledgeable in all aspects of by-pass pumping when installing a new Sewer Lift Station.

So you attained all the flow data on the sewage flows that the existing sewer lift station currently handles, now double it!

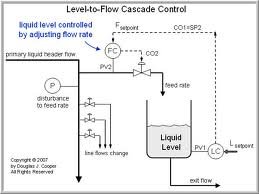

Most engineers will perform hydraulic calculations based on flows that are double the average flows into the station. It is vital that a team is assembled on any new Sewer Lift Station where the sewage must be by-passed. The Pump Supplier and the pump curve that is put forth for the specific Sewer Lift Station should be reviewed by all the team members including the owners’ representative, which is usually the design engineer. Important information that the Pump Supplier may not have like the by-pass operation is in front of a school or major department store will insure a detailed sewage pump by-pass plan!

Two separate plans for the same Sewer Lift Station.

The very point of this blog was to make clear the fact that you cannot have a successful placement of a new Sewer Lift Station without first confronting the existing sewer flows that are ever present on a Sewer Lift Station change out or retrofit. The government entity or private owner will not remember the nice job you did on replacing an old station with a high quality Taylor Made Pump Station if you flood a pristine river with raw sewage. The theory behind the two separate plans for each aspect of the Sewer lift Station build is the critical nature of the by-pass. The pump by-pass has to be planned to the last detail. The by-pass should be submitted to the design engineer for his or her review. When planning to replace an existing sewer lift station consider ordering a packaged sewer lift station from Taylor Made Pump Stations. The reasons to consider a packaged sewer lift station are many. A Packaged sewer lift station is less burdensome from the planning side of the equation and provides for peace of mind as you have one supplier to call should problems arise. At Taylor Made Pump Stations we will gladly help you with any pre-planning for by- pass pumping or other services you may need for a successful sewer lift station project. See you, next week at the station.