“See you at the station” Do you know the Definitions of the components that make up a Packaged Waste Water Lift Station?

Taylor Made Pump Stations “Writes The Book” or in this case a booklet on the definitions of the individual components that make a complete Packaged Waste Water Lift Station!

We will start with defining the basic parts of the Packaged Waste Water Lift Station.

- Packaged Waste Water Lift Station. Is a concept of packaging all the electrical, mechanical and structural components that go into the making of a complete operational water or waste water lift station. As a part of the definition of packaging it is meant to assemble beforehand and usually in a controlled environment such as a building structure.

- Lined Wet Well. A methods of casting in place a non-corrosive membrane into the inside walls, floor and top of a concrete waster water lift station. The material most commonly set into the wet well to form a liner are made up of poly vinyl chloride (PVC) or high density poly ethylene (HDPE) in varying thicknesses but most commonly 30mil.

- A Concrete Wet Well. When it is included as part of a packaged waste water lift station order is a reinforced precast structure formed in round sections called barrel sections in varying diameters and lengths .

The base section of the wet well is the floor it comes with an anti-buoyancy block which is generally

a thickened section of up to 18’’in diameter and also wider than the barrel sections, to create an

loading area to resist uplift of the structure. - Pre-Cored Pipe Penetrations. Usually applies to the situation of a waste water lift station having round holes pre-drilled to accommodate pipe entering the wet well. These core holes will be considerably larger than the pipe O.D. to allow for Elastomeric sealing products to be utilized.

- Field Core Pipe Penetrations. This mode of creating openings in a packaged waste water lift station is a service offered by Taylor Made Pump Stations and the equipment needed to drill the concrete structure in the field, is provided with the packaged waste water lift station. Field coring allows for a precise hole opening that may be required in the situation where an existing pipe elevation could vary.

- Valve vault. The valve vault in a waste water lift station is most commonly a square concrete box structure as manufactured by Oldcastle Concrete. The pre-cast structure comes in varying sizes but an average dimension to suit most municipal waste water lift stations is 4’ wide by 6’ long by 4’ deep. In most all cases in will come with dual or single lids. Hatches are made of galvanized stainless steel or aluminum that are made of stainless or aluminum for their anti-corrosion capabilities.

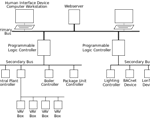

- Control Systems. Commonly conceived or designed for total automatic control of two motor driven pumps operating on standard 240V 3 Phase or 480V 3 Phase,(208 and 240V single phase are common on smaller HP motors, usually under 5HP).

- Programmable Logic Controller. (PLC) Is a digital computer used for automation of electrical/mechanical actions, such as control of “pumps, valves and warning alarms.” The abbreviation “ PLC” are registered

trademarks of the Allen Bradley Company (Rockwell Automation). The PLC is a “current time” system since output results must be produced in conjunction to input conditions within a limited time, otherwise unintended actions will occur.

trademarks of the Allen Bradley Company (Rockwell Automation). The PLC is a “current time” system since output results must be produced in conjunction to input conditions within a limited time, otherwise unintended actions will occur. - Liquid Level Monitoring. A wet well level is controlled commonly utilizing the following electronic equipment. Float Switches, present in many of today’s waste water lift station. These point level sensors comprised of a magnetic float moves in relation to the water’s surface. Usually tethered off a solid pole or rack floats are tied off to create an actuation range in which a certain volume of liquid will cause a rise or drop in the level of the liquid and thus cause a pump to turn on or off. Included as part of the packaged waste water lift station. These read type switch mechanisms can either be single pole, single throw or double pole, double throw.

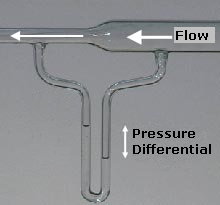

- Transducer. A hydrostatic pressure sensor is an example of a transducer; a transducer contains sensors and converts it signal to an electrical signal to operate other mechanical or electrical devices.

- Contact Ultrasonic Sensors. A low energy field mounted sensor and integral solid state amplifier. These sensors will auto operate pumps, solenoid valves and high/low alarms.

- Power Distribution Block. A main distribution block sized for incoming line power to a panel.

- Surge Protection. Made of a oxide silicon varistor. A lightening suppressor must be able to handle surges of a minimum of 60 thousand amps or 1,500 Joules.

- Phase Monitors. Where 3 phase motors are installed a phase monitor is employed to monitor phase loss, under voltage and phase sequence with a single pole double throw switch.

- Variable Frequency Drives. Variable frequency drives operate under the principal synchronous speed of a AC motor is determined by the frequency of the AC supply and the amount of poles state of winding according to the relation: RPM= {{{60 \ times f}\over {p}}}.

- Circuit Breakers. Taylor Made Pump Stations specifies in each packaged waste water lift station thermal magnetic breaker for each load served one for the transformer and one for each motor served.

- Contactor Overload Relay. For motors less than 20 HP a magnetic across the line HP/Current rated contactor with a ambient temperature overload relay.

- Soft Starts. Directly relates to reducing the torque delivered to the electric motor. This can be accomplished via a mechanical clutch, fluid drive, magnetic coupling or any derivative thereof that allows the across the line starting while decreasing the shaft torque to the load and thus avoid torque shock. Taylor Made Pumps Stations recommends soft starts as a money saving investment that increases overall MTBF, mean time before failure of the pump loader.

For you readers of my “Blog For The Nog,” ” See You At The Station”, when you google definitions of the components that make up a packaged waste water lift station you will have the terms in a click of a button.