See You at the Station – NPSH

A Positive Story about Managing the Liquid Limit in a Waste Water Lift Station

Here is the good news about understanding the concept of, Net Positive Suction Head or NPSH. If you understand the theory of Bernoulli’s principle you probably do not need a basic overview of NPSH. The bad news is maybe you haven’t the foggiest idea of how this mathematical equation helps one determine the value of NPSH.

After sometime spent on the internet I believe the best definition of NPSH:

“NPSH is used to denote the suction performance of a pump without regards of the system to which it is installed.”

Sounds simple enough, but it is not.

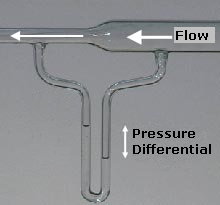

In all actuality submergence level of a pumps intake in relation to the surface of the water above creates a better picture of what we are attempting to define. Remember that the height of water produces head, or what is called pressure head. The distance of the pumps intake below the surface of the liquid gives us the basic concept of suction head.

With the basic understanding of NPSH you can better conceive of what is meant NPSHa or suction head available. As an installer of packaged waste water pump stations, NPSHa became easy for me to understand. I associated the dynamic of suction head available by thinking of the term available as synonymous with tools or means available. For example, nature supplies a means or tool for those of us concerned with suction head available in the form of our atmosphere. This important sphere (slightly more important as it supplies us with the oxygen we breathe) is an element in creating pressure head on the water’s surface and thus helping to create suction head available.

At sea level the atmosphere produces the same amount of pressure as a column of water approximately 30’ high. Hydraulic modeling is something that is usually beyond the capabilities of station builders. When it comes to a Basic simulation of how a pump in a waste water lift station performs in relation to NPSHa ,(net positive suction head available) the station supplier can run some basic empirical tests.

The applications engineer can put the pumps through some differing suction head conditions that would apply to the hydraulic performance of the pumps under differing liquid levels in the waste water station. The packaged waste water station designer, as a professional in the industry, has to be concerned with cavitation and should attain from the manufacturer the NPSHr (net positive suction head required). In any “run up” performance test on the pumping operation cavitation is a paramount concern. The potential for the temperature of the effluent in the waste water lift station to increase can affect the NPSHa.

It’s getting hot in here!

All liquids have a vapor pressure. Vapor pressure of a liquid is the transformation of a liquid to a gas. As the temperature of the liquid increases vapor pressure rises to the point of gas escaping in the form of bubbles or cavities in the liquid. These air pockets will collapse as they go from the low pressure vortex to the pressure stream. There is actually less NPSHr in the pumping of warmer water, but the challenge is to keep the fluid in its liquid form and warm water poses a challenge in this respect.

In closing:

There are many mathematical equations that analyze fluid flow dynamics problems where cavitation may occur. Math formulas are tools that give the pump technician the ability to check the actual field and environment conditions against known mathematical values. Computing all the variables that contribute to cavitation in the submersible sewage pump can be done by a wonderful program called excell. So, to keep a waste water lift station pump on the positive side of suction head and positively produce a pump station with a long MTBF, let’s not get negative.