For sale one “Taylor Made pre-fabricated Waste Water pump station”

Play along with me on this blog as I attempt to create the analogy in the sale of a used pre-fabricated waste water Pump station to that of the actions a person might take in selling their automobile. It is a comparison that makes one think.

The public works manager or the asset manager should equate the regular maintenance of a pre-fabricated waste water pump station to its current “used” value along any point of its life cycle. I can’t think of any method that is better to show the current value of a used asset, than to put it up for sale.

So, here we go, are you ready for your first buyer?

Our interested party is a very sophisticated customer named John. John reads a lot of blogs, including “See you at the pump station” so he is really in the know. Now, our professional public works representative, who we will call Tom, is already a little rattled as he can’t find the “Pump Fax” report and he knows the buyer will want to see the work report on this 2007, Taylor Made prefabricated waste water pump station.

Alas, at the last moment the work order logs are located, and after a look our customer states that the reports are well formatted. Tom is quick to point out that the detail in the paper work specifications from the inspection and work order sheets as well as the OSHA required confined space signage is included in the purchase of the Taylor Made pre-fabricated waste water pump station”.

John knows the value of the “Pump fax” report but is giving no sign that this station is the one. Being a good asset manager of this imaginary city , John wonders “who would find their financial situation so dire to have to sell a sewage pump station?’”

Tom kicks his salesmanship 101 into gear, and mentions the energy efficient motors that come with the purchase of the “Taylor Made sewage pump station”. All the documents are there in the purchase order and its plain that Taylor Made Pump Stations, one of the few “Energy Trust” pump station builders with this designation, puts a great deal of emphasis in pumping optimization from both the hydraulic design as well as motor efficiency.

John finally nods in approval and almost shows his enthusiasm in this rare opportunity to purchase a low hour Top of The line Taylor Made pre-fabricated waste water pump station. Noticing this Tom moves on the performance aspect of the drives, which are likened to an Energy-Efficient “Gas Pedal” for electric motors, these speed controllers are of crucial importance in saving energy and reducing operating costs. The Taylor Made pre-fabricated waste water pump station, was specified for the pump supplier to utilize their controls and VFD’s for efficiency and single source responsibility.

The Taylor Made Pre-fabricated waste water station has both Brains & Beauty.

It was becoming plain to Tom that John was very impressed with all the features of the station as well as the maintenance records produced by the city. The PLC, with a Modbus connection provides all level control monitoring, status and alarm conditions notifications would be easy for his small public works department to learn and operate.

Now it is time to check under the hatch. John, had already done his homework on the 25HP submersible non-clog pumps and with under 1,000 hours on each pump he had little concern that the pumping ends and motors were of high quality and “top flight”(not to relate the pumps to the high quality brand of a similar sounding name, but excellent sewage pumps none the less).

The Taylor Made Pre-fabricated waste water station is also designed with easy clean in mind!

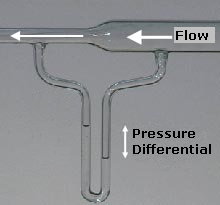

John, our buyer couldn’t help but notice the bright red tube standing out at the top of the station. He recognized the Patented EZZ-Klean device as the asset manager of his city he had them installed in two of his pre-fabricated waste water pump station. He is very aware of how they increase the MTBF (mean time before failure) of the pump station. John said, “I really haven’t seen anything with this station that I don’t like. I cannot take the concrete wet well with me, but if you will throw in the top and hatch we can put the lid on this deal”. Tom, thought it would be a month or two before this sewer line was converted to a gravity line and thus the station could be decommissioned and removed. So If you’ll excuse the pun, it was a “crappy” deal but both men came out smelling good.

Wastewater lift station cleaning can be a simple process. Our patented EZZ-Klean system is comprised of a permanent High Density Polythylene (HDPE) wide mouth intake and HDPE pipe. It runs to the top of the wet well and is easily connected to a VAC Truck or similar equipment. The VAC truck simply sucks out debris and muck.

Wastewater lift station cleaning can be a simple process. Our patented EZZ-Klean system is comprised of a permanent High Density Polythylene (HDPE) wide mouth intake and HDPE pipe. It runs to the top of the wet well and is easily connected to a VAC Truck or similar equipment. The VAC truck simply sucks out debris and muck.

infomd@structure1.com

infomd@structure1.com