The Northern Most US Pump / Lift Station Shemya, Alaska

The Most Northerly US Pump / Lift Station Shemya, Alaska

The Northern most pump station in the US was build by Taylor Pump Stations! We completed this Shemya, Alaska pump / lift station in early 2019! Taylor Pump Stations secured the contract because of our ability to work within the strict time constraints dictated by Alaskan weather. We also met funding requirements and we were able to deliver on the Engineer’s tough requirements. “I need a waste water lift station that will work in our corrosive marine environment.”

Shemya Island, Alaska – A Harsh Maritime Environment

Shemya Island, Alaska, Home of North Most US Pump Lift Station by Taylor Pump Stations Photo Credit

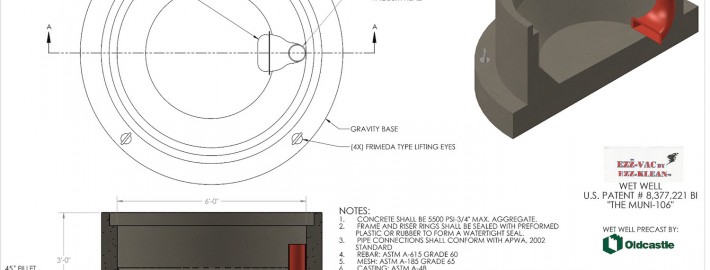

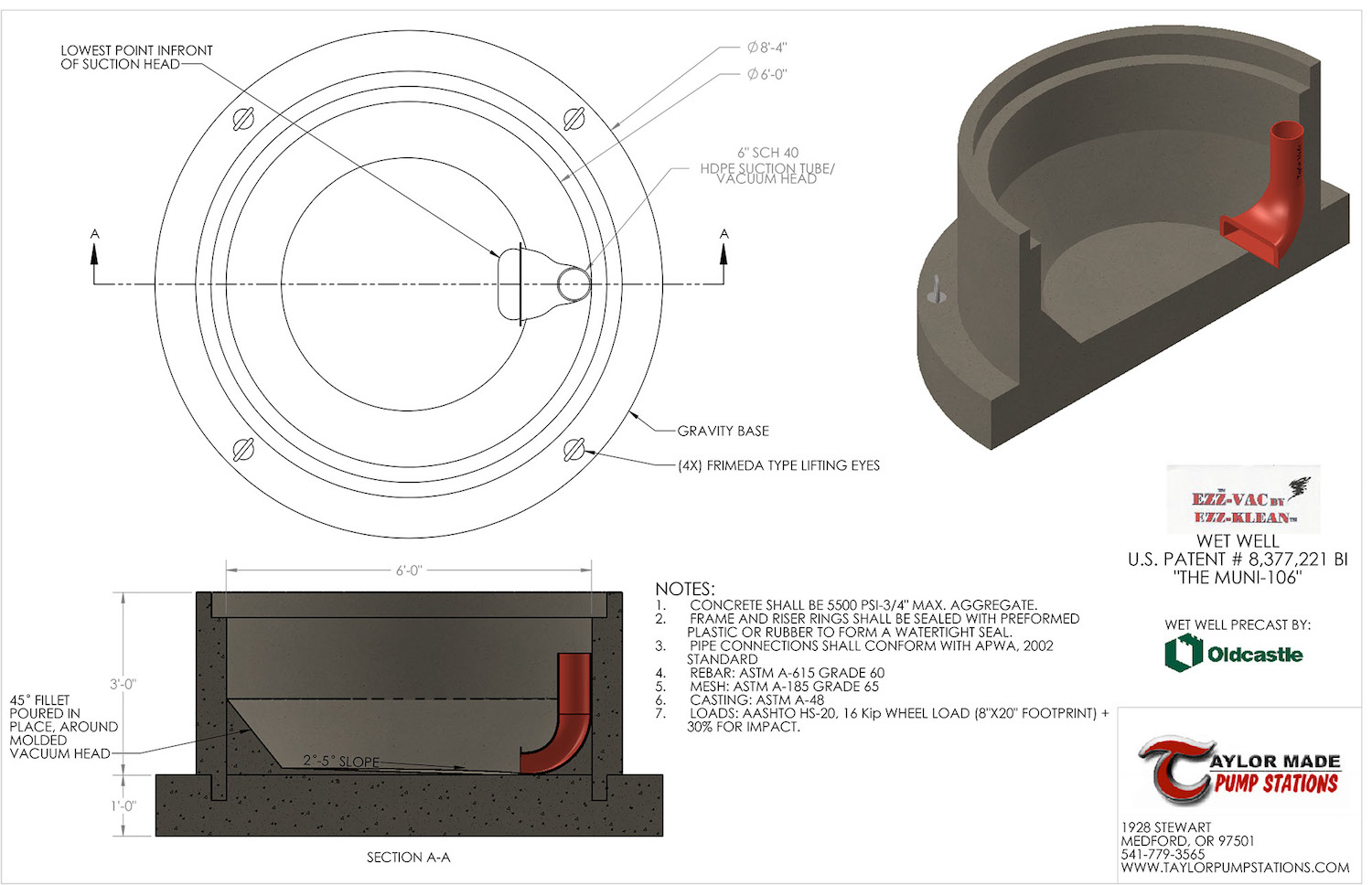

We can design our Pump / Lift Stations around the extra heavy-duty HDPE no-leak “Muni 105” wet well. Along with 316 fasteners and rails with HI build epoxy coating on all layers and components. Because of high wind and sea water exposure in Shemya, Alaska, a small island in the Bering Sea, a NEMA 4X HDPE enclosure was stipulated to best offset the harsh marine environment. This pump down panel has external LED lights for each pump with alert lights for on/off states. A Manual on/off/ run toggle is provided for each motor. The Muni-105 features alteration of Duplex Pumps after each pump cycle.

Alarming is both visual and audio, with a bright red flashing beacon placed on the side for wetter, marine environments. A push to silence switch is located on the inside of the door. This is a class 1 sewage environment panel with intrinsically safe relays for the flow control switches. Flow control is via mechanical reed type switches operating for ‘lead then lag,’ and ‘high both pumps,’ the ‘high/high float’ insures redundancies for alarm condition.

Working with Special Requirement and in Difficult Places is our Specialty

We specialize in working with the unique requirements of every environment including harsh environments. Our pump /lift station in Shemya, Alaska is one of many examples of how we surpass all expectations and adapt to the special needs of each individual project.

Public Domain https://commons.wikimedia.org/wiki/File:Shemya_island_Cable_Bowl_N_shore.jpg

Public Domain https://commons.wikimedia.org/wiki/File:Shemya_island_Cable_Bowl_N_shore.jpg